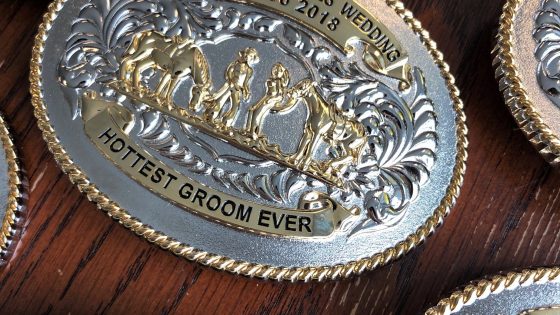

Buckles for belts are an element of fashion and function. They serve as a mechanism to secure a belt around the waist. Custom belt buckles, in particular, can be a statement piece that adds personality and style to an outfit.

They have been a staple accessory for both men and women as they provide a unique opportunity to showcase individuality and brand identity. Additionally, they can be promotional items, awards, or simply as a way to express personal style.

In this buckles blog, we will go through the creation of buckles for belts from conceptualization to production and delivery.

CONCEPTUALIZATION

GATHERING INSPIRATION AND IDEASTo begin the process, the designer must gather inspiration and ideas. It involves researching different styles, materials, and designs to get a feel for what is possible. The designer may explore different cultures and traditions, and visit museums or galleries to find inspiration.

This process allows the designer to understand what works and what doesn’t, helping them create a unique, high-quality product.

Once the designer envisions the design they want to create, it’s time to sketch out the initial designs on paper.

B. SKETCHING AND INITIAL DESIGN

These sketches will help the designer visualize the final product. It allows them to share their ideas with the client for feedback before moving forward with the final product.

Sketching allows the designer to experiment with different shapes, colors, and materials without committing to a final product.

The designer must also consider the client’s needs and preferences during the sketching and initial designing of the buckles for belts. It is what collaboration is for.

- COLLABORATION WITH THE CLIENT

Collaboration with the client is an essential part of the design process. The designer must understand the client’s needs, vision, and preferences to create the best belt buckle. The designer must also consider the client’s budget, timeline, and any other specific requirements they may have.

This collaboration ensures that both parties are satisfied with the progress and direction of the project.

MATERIALS AND MANUFACTURING

- SELECTING OF MATERIALS

Some popular materials used for belt buckles include metals, leather, wood, and plastic. The designer must also consider durability, cost, and availability.

Once the materials are selected, it’s time to move on to the manufacturing process.

- CHOICE OF THE MANUFACTURING METHOD

The choice of manufacturing method will depend on the designer’s budget, timeline, and design specifications. There are several methods to go through with this:

Casting is a process that involves pouring molten metal into a mold. This method is ideal for creating intricate designs and shapes but can be expensive and time-consuming.

Stamping involves using a die to cut out the buckle’s shape and design from a metal sheet. This method is ideal for creating simple designs and is typically less expensive than casting.

Engraving involves etching the buckle’s design onto a metal surface using a laser or other tool. This method is often used with casting or stamping and is ideal for creating detailed designs and logos.

Machining involves using a computer-controlled machine to carve the buckle’s design from a metal block. This method is ideal for creating precise and intricate designs but can be expensive and time-consuming.

- CREATION OF A PROTOTYPE

Creating a prototype allows the designer to test the chosen materials and manufacturing methods before making the final product.

Before creating the final product, the designer should create a prototype to test the chosen materials and manufacturing methods. The prototype can be a small-scale version of the final product made using the same materials and manufacturing methods.

It allows the designer to make any necessary adjustments to the design or manufacturing process. Also, to see how the materials hold up over time.

After creating a prototype, it’s time to evaluate its performance and refine the design of the buckles for belts.

REFINEMENT OF BUCKLES FOR BELTS

- TEST AND EVALUATION OF PROTOTYPE

The designer should test the buckle’s durability, functionality, and aesthetics. Doing so determines if anything has to change in the design or manufacturing process. It may involve subjecting the buckle to stress tests. Also, evaluating the quality of the materials and assessing the buckle’s overall appearance.

- FEEDBACK AND REVISIONS

Feedback is an essential part of the refinement process. It matters in making any necessary revisions to the design before creating the final product. The designer can then ensure that the final product is exactly or even better than what the client wants. Revisions may include changing the materials, manufacturing process, or overall buckle design.

It is important to note that the feedback and revisions process may involve multiple rounds of testing and evaluation. The designer should continue to refine the design and seek feedback until the final product is perfect for the client.

- FINALIZATION OF DESIGN

The refinement process involves evaluating the initial prototype and making the necessary changes to improve the design, durability, functionality, and aesthetics. This process may include testing the prototype, assessing the quality of the materials, and refining the manufacturing process.

Finalizing the design involves creating a detailed plan for the belt buckle production. It includes selecting the materials, refining the manufacturing process, and specifying the dimensions and other features of the buckle.

Potential issues that may arise during production are considered during this process. It may include materials, manufacturing processes, or quality control issues. Once the final design has been created and approved, it is time for production.

PRODUCTION AND DELIVERY

- MASS PRODUCTION OF THE BUCKLES FOR BELTS

Buckles for belts must be produced according to the given specifications and quality standards. It may involve selecting high-quality materials, refining the manufacturing process, and monitoring the production process to identify potential issues.

Quality control and inspection are critical to ensure that the final product satisfies the designer’s specifications and quality standards during production. It may involve conducting visual inspections of the buckles for belts to identify any defects or flaws.

Mass production involves creating large quantities of belt buckles. There are various manufacturing processes to do this.

Die-casting involves injecting molten metal into a mold or die, which is then cooled and removed to produce the final product. Die-casting is a popular process for creating intricate designs and detailing as it allows for precise and consistent results. It can be used with various metals, including zinc, brass, and aluminum.

Stamping involves a punch die set that shapes the metal into the desired form. It is common for large-scale production runs and is a cost-effective process for creating simple designs and patterns. However, it may not be suitable for complex designs or fine details.

Forging involves heating metal to a high temperature and then shaping it using a hammer or press. This process is often used for creating thicker, heavier buckles for belts and can produce a unique texture and finish. However, it can be more time-consuming and expensive than die-casting or stamping.

Laser cutting is a precise and efficient method of cutting metal into intricate shapes and designs. It is often used with other manufacturing processes, such as die-casting or stamping, to create more complex designs.

Each of these manufacturing processes has its strengths and weaknesses. Whichever to use will depend on the desired design, quantity, and budget.

- QUALITY CONTROL AND INSPECTION

The process of quality control and inspection ensures that the final product is free from defects or inconsistencies.

Quality control begins during manufacturing, with regular checks and inspections verifying each step. For example, during die-casting, the mold and equipment are regularly checked. Doing so will ensure the metal is at the right temperature and poured at the right speed. Similarly, during stamping, the die and punch are checked to ensure they are creating the desired shape and pattern.

Once manufactured, they undergo a final inspection to ensure the required quality standards are met. It involves checking for defects such as scratches, dents, or discoloration. Also, verify that the buckles meet the desired size, weight, and shape.

Quality inspection is not just limited to the manufacturing process. It also extends to the packaging and delivery stages. The buckles for belts are carefully inspected and packed to protect them from damage during shipping.

- DELIVERY AND PRESENTATION TO THE CLIENT

During the delivery phase, ensure that the buckle arrives at its destination safely and in the highest quality possible. It may involve working with a logistics company to coordinate shipping and delivery. It will ensure the packaging is secure and well-protected during transport.

Once the buckles for belts are delivered, it is time to present them to the client. The designer should propose the product highlighting its unique features and benefits. It may involve creating a custom presentation or video that showcases the buckle’s design, materials, and craftsmanship.

During the presentation, the designer should also take the time to address any concerns or issues the client may have. It is the perfect opportunity to demonstrate the designer’s commitment to quality and customer satisfaction. Doing so will build a strong relationship with the client.

INTRODUCING, CUSTOM BUCKLES FOR BELTS AUSTRALIA

The physical process of creating custom buckles for belts is highly intricate and challenging. It requires a great deal of skill and expertise from conceptualization, to manufacturing, and refinement.

A custom belt buckle can be a great addition to your wardrobe. It can also be a unique gift for someone special or a way to showcase your brand identity. So, if you’re considering a custom belt buckle, take the next step and reach out to Custom Belt Buckles Australia.